The current demand for integrated circuits (ICs) is at an all-time high due to both long-term trends such as the Internet of Things, autonomous driving, and cloud computing, as well as short-term supply chain disruptions. However, IC manufacturers are struggling to keep up with the demand due to the industry’s capital intensity and long ramp-up times. This has led to historically high utilization rates in fabs. To address this, both IC manufacturers and governments are investing an unprecedented amount of capital over the next few years. It is estimated that IC manufacturer capex will reach $190 billion in 2022, which is three times the amount spent in 2012.

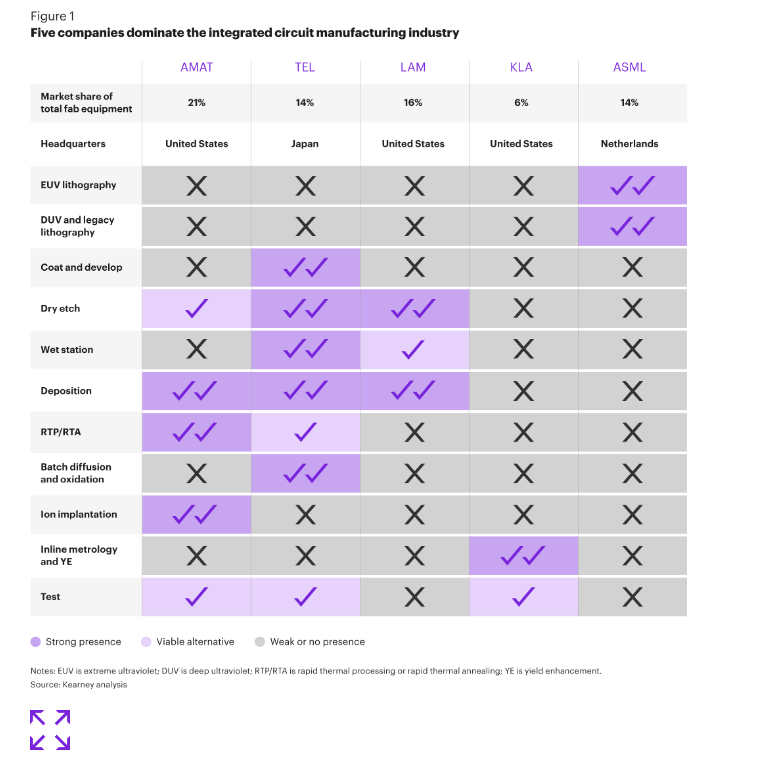

A major portion of this investment will be allocated to wafer processing equipment. However, the front-end IC equipment manufacturing industry is dominated by just five vendors who control around 75% of the market. IC manufacturers face a challenging environment where there is high demand but a limited number of suppliers, and these suppliers do not compete in the same equipment sub-sectors (see figure 1). This puts manufacturers in a difficult position to negotiate with equipment suppliers. To gain a competitive edge, manufacturers will need to think outside the box.

The principles of game theory can provide significant benefits in seemingly precarious negotiation situations. The approach utilizes a variety of techniques, such as expanding the value of the agreement by offering preferred access to equipment suppliers, creating information asymmetry through blind bidding, reducing risks with revenue sharing, or escalating competition with parallel negotiations between major suppliers. A well-executed process and high credibility are crucial. Comparable success has been observed in other technology sectors, like telecommunication equipment, where controlled circumstances transformed into unrestricted bidding resulting in substantial savings.

In essence, the objective is to convert a monopoly into actual competition. Drawing on our experience in assisting clients with significant capital purchases, there are three prerequisites for a successful outcome through competitive game-theory negotiations:

- Keep options open. Multiple viable options must be available that deliver satisfactory manufacturing performance and are feasible to integrate with the customer’s manufacturing environment.

- Create high stakes. The customer must be valuable to the equipment manufacturer, and there must be a fear of losing the customer to a competitor. As capacity is becoming more regionalized and political influence grows, recapturing customers could become challenging.

- Establish a win-win situation. There must be a significant potential for mutual value, such as a longer warranty, a lower sales price, or additional post-installation support for the customer in exchange for an exclusive period for the supplier. The concessions must be meaningful.

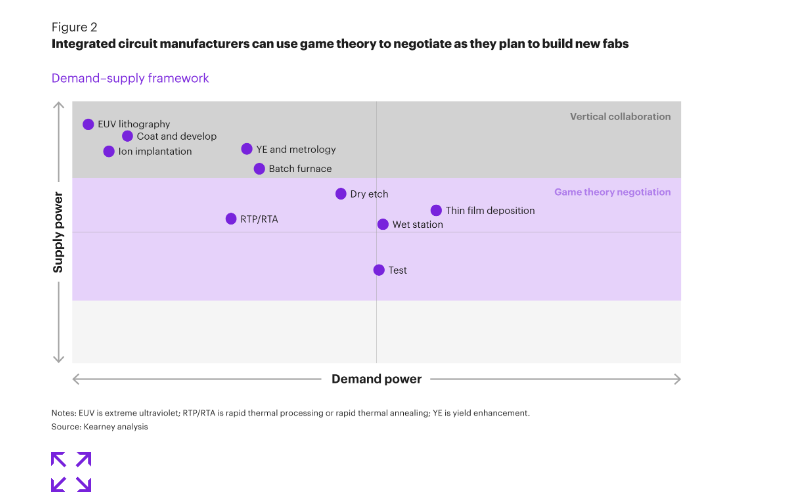

Forward-thinking IC manufacturers are assessing their demand-supply position for all equipment subsectors and determining where to apply game-theory negotiation while planning new fabs (refer to Figure 2). After identifying opportunities, manufacturers must establish a competitive bidding atmosphere for prospective suppliers. First, bidding must occur simultaneously, with suppliers bidding against each other in isolation. Second, customers must establish standardized bidding templates with essential parameters like purchase price, acceptable equipment performance criteria, warranty period, spare parts, or ramp-up support. Lastly, a central control tower staffed with key stakeholders must make the final decision on bids.

By fostering a competitive environment and leveraging the power of game theory, IC manufacturers can strengthen their bargaining position with equipment suppliers and obtain concrete benefits for their operations, such as reduced capital costs and improved supplier support for their fabs.

To gain an edge in negotiations, it is crucial to develop a sound strategy and implement it rigorously. Anticipating every possible move and making suppliers aware of each other’s positions can alter the competitive dynamics and transform a seemingly hopeless situation into a genuine negotiating advantage.